You depend on your trailer to work reliably and safely as you use it to transport goods. Without adequate trailer care, however, you’ll likely find yourself dealing with expensive and potentially dangerous issues. Understanding trailer maintenance practices and developing an effective upkeep plan will save you money, time and stress. Use these trailer servicing tips to keep your hauler in top condition for years of safe, reliable use.

Importance of Trailer Maintenance

Routine trailer maintenance is essential for ensuring your safety on the road. Trailers — whether used for cargo, travel or recreation — see extensive wear and tear during their life span. Neglecting to maintain them can lead to severe failures like tire blowouts, brake malfunction and structural damage. These issues jeopardize your safety and pose risks to other drivers.

Following a trailer maintenance plan can significantly extend your trailer’s life span. Trailers are an investment, and proper care can help protect that investment for the long term. By addressing minor issues before they become major problems, you’ll save money on costly repairs and be able to enjoy your trailer for many more years.

Benefits of Regular Trailer Care

Investing in regular trailer maintenance yields many benefits for those looking to get the most out of their haulers and stay safe on the road. Developing and sticking to a maintenance plan will allow you to realize the following advantages of responsible ownership.

Safety Benefits

One of the most significant trailer maintenance benefits is improved safety. Keeping your hauler in excellent shape promotes the following:

- Improved road safety: One of the most compelling reasons for routine trailer maintenance is safety. Your trailer is an extension of your vehicle, so its mechanical components must be in optimal condition to ensure safe road operation. Regular maintenance helps you identify and address potential issues before they become dangerous.

- Accident prevention: Neglecting maintenance can lead to accidents caused by mechanical failures — for example, a poorly maintained brake system may yield inadequate braking power, increasing your collision risk. Keeping your trailer properly maintained reduces the chances of accidents that result in injuries or fatalities.

- Protecting others: A malfunctioning trailer can pose risks to nearby vehicles, pedestrians and cyclists. Prioritizing safety through regular trailer care is a responsible choice that contributes to safer road environments for everyone.

Financial Benefits

You’ll also enjoy these financial benefits when you invest in your trailer’s maintenance:

- Cost-effective upkeep: Routine trailer maintenance is a wise financial investment. It’s far more cost-effective to conduct scheduled checks and address minor repairs than to deal with major issues stemming from neglect. Something as simple as regularly checking and maintaining proper tire pressure can significantly extend your tires’ life span, saving you from the expense of premature replacements.

- Prevent costly repairs: Components like brakes, axles and suspensions can be expensive to repair or replace. Regular maintenance, like brake adjustments and lubrication, can prevent these systems from deteriorating to the point of needing extensive overhauls, ultimately saving you money.

Longevity Benefits

You’ll extend your trailer’s service life with regular maintenance, along with seeing safety and financial benefits. Here’s how maintenance can increase your trailer’s longevity:

- Extended life span: Trailers are often exposed to harsh conditions, including heavy loads and environmental factors. Routine maintenance allows you to promptly identify and address minor issues so you can prevent them from escalating into major problems. Doing so extends your trailer’s life span, allowing it to serve you well for many years.

- Optimal performance: A well-maintained trailer operates at peak performance. When components like wheel bearings and suspension systems function as intended, they contribute to smoother and more efficient towing. A better ride enhances your trailer’s longevity and improves your overall towing experience.

Resale Value Benefits

Even if you have no current plans to resell your trailer, keeping it in good condition with regular maintenance can make doing so easier. Expect some of these resale benefits when you invest in routine trailer maintenance:

- Attractive to buyers: When the time comes to sell or trade in your trailer, a well-maintained unit is far more attractive to potential buyers or trade-in partners. It demonstrates responsible ownership and suggests that the trailer is in good condition.

- Higher resale value: Proper maintenance can even enhance your trailer’s resale value. Buyers are often willing to pay more for a trailer with a documented history of regular maintenance, making it a wise investment in the long run.

Trailer Maintenance Tools and Supplies

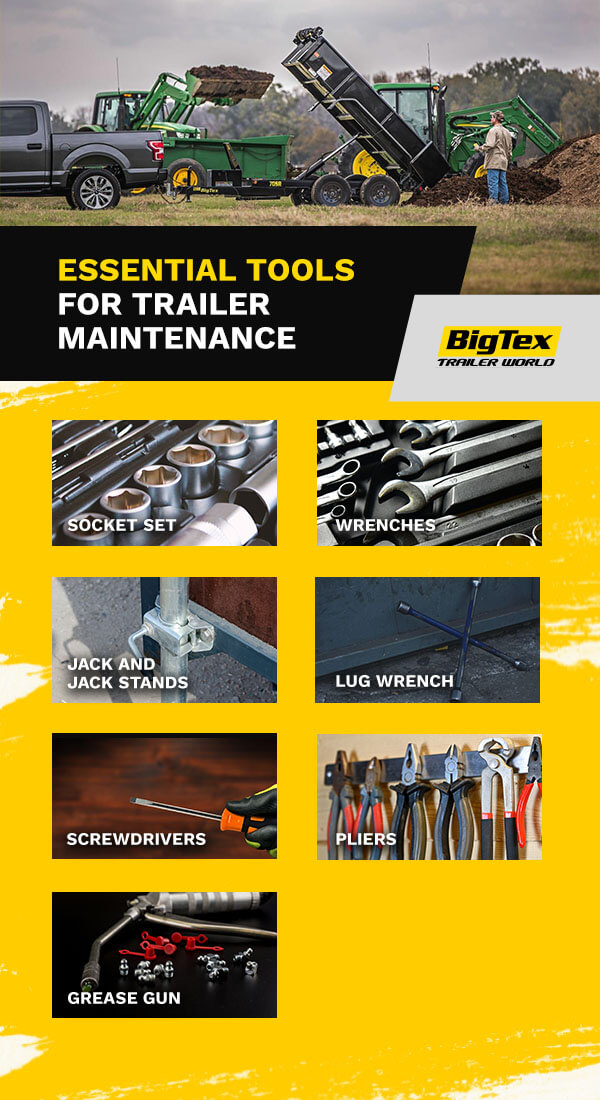

Before starting your trailer maintenance protocol, you need the right equipment. Trailer maintenance calls for a set of essential tools and supplies to effectively inspect, service and repair various components. These resources are vital for maintaining your trailer’s safety, longevity and performance. Here’s a closer look at what you need:

Essential Tools

These tools will help you get your maintenance done quickly and effectively:

- Socket set: A full socket set with various sizes lets you loosen and tighten nuts and bolts across your trailer.

- Wrenches: Combination and adjustable wrenches help with tightening and loosening fasteners.

- Jack and jack stands: Lifts and supports are indispensable for lifting your trailer to inspect or service tires, brakes or the undercarriage.

- Lug wrench: Used for removing and installing lug nuts when changing tires.

- Screwdrivers: Both flathead and Phillips-head screwdrivers are handy for working with smaller fasteners.

- Pliers: Pliers help with gripping and bending, and they’re especially useful for electrical work.

- Grease gun: Essential for greasing wheel bearings and other moving parts to prevent wear and friction.

Recommended Supplies

You’ll want these supplies on hand to help you complete your trailer maintenance routine:

- Grease: High-quality grease suitable for your trailer’s components is vital for lubrication.

- Cleaning supplies: Cleaning agents, brushes and rags will help you keep your trailer free from dirt, grime and rust.

- Brake fluid and hydraulic oil: If your trailer has hydraulic brakes, you’ll need the appropriate fluids on hand for maintenance.

- Tire repair kit: A tire repair kit with patches, plugs and a tire inflator can be a lifesaver in case of minor tire damage.

- Safety gear: Safety glasses and gloves are often essential while performing maintenance tasks. If you’re using loud tools, consider ear protection as well.

- Owner’s manual: Always have your trailer’s owner’s manual on hand for specific maintenance guidelines and specifications.

Having the right tools and supplies on hand ensures you can perform routine trailer maintenance efficiently and frequently, letting you reap the full benefits of having an established upkeep plan.

Routine Trailer Repairs and Maintenance Tips

Routine maintenance is essential to keep your trailer in top condition for optimal performance and safety. Here are some travel trailer maintenance tips to help you stay on top of trailer care:

- Washing and cleaning: Cleaning your trailer regularly will ensure you can keep an eye on its component health. Remove dirt, grime and road debris from the exterior, including the frame, body and undercarriage. Pay special attention to the underside, where dirt and debris can accumulate. Use a high-pressure washer to thoroughly clean the undercarriage, especially after off-road trips. After washing, inspect the trailer for signs of rust or damage. Treat any exposed metal surfaces with rust-resistant coatings or paint to prevent corrosion.

- Lubrication: Wheel bearings and moving parts like hinges, latches, ramps and jacks need regular lubrication. Lubrication minimizes wear and ensures smooth operation. Make sure to check seals and gaskets for damage or water as well. Replace damaged seals to prevent lubricant leakage and contamination.

- Bearing buddy: Bearing buddies help maintain proper grease levels in wheel bearings. They have a spring-loaded piston that keeps pressure on the grease, pushing it into the bearings when needed. With a bearing buddy in place, you can add grease without disassembling the hub, making the process more convenient. Regularly inspect the bearing buddies to ensure they maintain the correct pressure.

- Regular inspections: Regular visual reviews before and after your trips can help you catch issues early before they become dangerous. Look for visible damage like cracks, dents and rust. Check your tires, coupler, hitch and safety chains for issues. Make sure they’re all functioning correctly.

- Tire maintenance: Perform routine pressure checks — properly inflated tires improve fuel efficiency, towing stability and life span. Use your manufacturer’s guidelines to achieve the correct tire pressure. Additionally, check the treads for signs of wear. Uneven wear may indicate alignment or suspension issues. Rotate tires as recommended to ensure even tire wear and extended life span.

- Wheel bearings: Grease wheel bearings according to manufacturer instructions. You should also check for grease leakage around the wheel hubs, which may indicate a failing seal. Address leaks promptly to prevent bearing damage and potential wheel loss.

- Brake checks: Test your brakes regularly to ensure they engage as they should. If you notice issues like delayed or uneven braking, consult a professional for inspection and adjustment. You might also need to periodically adjust your brakes for optimal performance. Finally, inspect brake pads and drums for wear and damage and replace them as needed.

- Lights and wiring: You should make sure all trailer lights work correctly before each trip. Check your wiring harness for signs of wear, damage or loose connections. Any corroded or frayed wires need to be replaced.

- Safety chains and hitch: Examine safety chains for signs of wear, damage or rust. Look for any weak links, cracks or stretched sections. Replace any chains with issues promptly to maintain a secure connection between the trailer and the towing vehicle. Inspect the hitch and ensure it functions properly to prevent accidents.

- Floor and deck: Check out your trailer’s floor and deck for weak spots, cracks or rot. Walk across the surface to detect any soft or spongey areas, as damaged sections compromise load-bearing capacity and safety. If you find any issues, address them quickly by having a professional repair or replace the damaged areas.

- Coupler and locking mechanism: Make sure the coupler engages securely with the towing vehicle’s hitch ball. Verify that all locking mechanisms — including safety pins and locks — are in place and functioning correctly. Lubricate the coupler and locking mechanism to prevent corrosion and ensure smooth operation.

- Suspension: The suspension system plays a crucial role in trailer stability. Examine suspension components for signs of wear, damage or rust. Look for cracked or broken leaf springs, leaking shock absorbers or misaligned parts. If you identify any issues, consult a professional for proper diagnosis and replacement. A well-maintained suspension system enhances towing stability and safety.

- Rust prevention: Rust can weaken your trailer’s frame and components, leading to safety hazards. Identify trailer areas susceptible to rust, like exposed metal surfaces, welds and joints, and treat these areas with rust-resistant coatings or paint. Regular touch-ups can significantly expand your trailer’s life span.

- Load distribution: Proper load distribution is crucial for safe towing, as incorrectly distributed weight can lead to handling problems. Always place loads on the trailer accordingly and use appropriate tie-downs and securing methods to prevent shifting during transport. Be sure to adhere to weight limits specified by the manufacturer — overloading can strain the trailer’s components and lead to unsafe towing conditions.

Following these trailer maintenance tips will help ensure your trailer remains safe and capable of many years of use. Regular inspections and proactive maintenance practices contribute to trouble-free towing experiences while minimizing the risk of unexpected issues on the road.

Creating a Trailer Maintenance Schedule

Regular trailer maintenance is essential for ensuring your trailer’s safety, longevity and performance. While you should always consult your model’s owner’s manual for manufacturer-specific recommendations, you can use the following schedule as a general guide to help you get started with trailer maintenance.

Trip Maintenance

Before each trip, give everything a quick once-over to catch any issues before you hit the road:

- Conduct a visual inspection of your trailer.

- Check for any visible damage, loose fasteners or missing parts.

- Ensure all lights are working correctly.

Monthly Maintenance

You’ll want to perform these tasks every month. Monthly maintenance will keep your trailer in peak condition and make it as safe as possible to haul. Check these areas:

- Tire inspection: Check tire pressure and look for signs of wear or damage. Inflate tires to the recommended pressure and perform timely rotations as needed.

- Wheel bearings: Grease wheel bearings according to the manufacturer’s guidelines. Regular greasing prevents overheating and extends bearing life.

- Brake check: Test the trailer’s brake system to ensure it’s working correctly. Adjust brakes if necessary and inspect brake components for wear.

- Lubrication: Lubricate any door or gate hinges on your trailer.

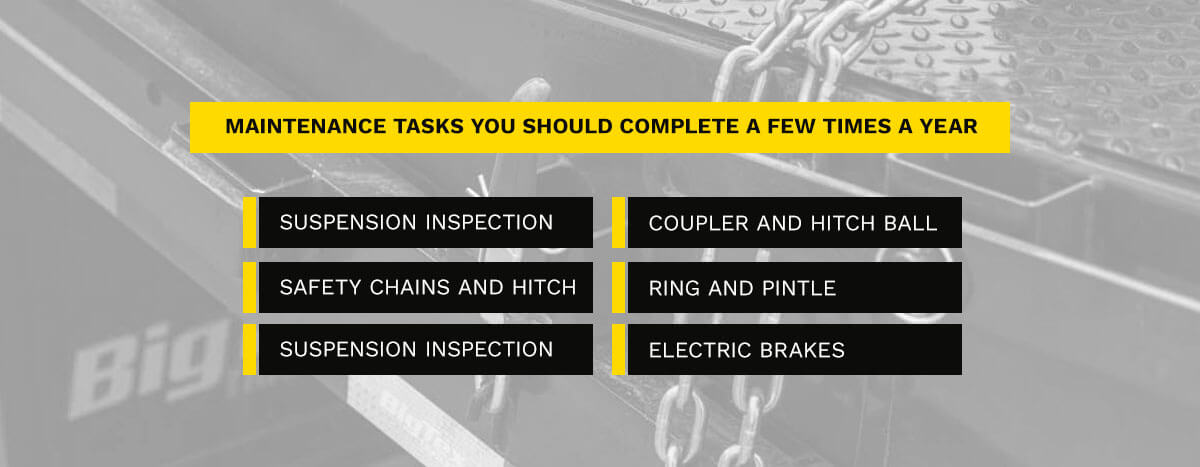

Seasonal Maintenance

You’ll want to perform additional maintenance every season to ensure everything works. Additionally, seasonal checks will help you prep your trailer for the coming weather changes. Here are the maintenance tasks you should complete a few times a year:

- Suspension inspection: Examine leaf springs, shock absorbers and suspension components for signs of wear or damage. Replace worn parts as needed.

- Safety chains and hitch: Inspect the safety chains and hitch for wear, rust or damage. Lubricate moving parts to prevent corrosion.

- Coupler and hitch ball: Examine these components for cracks, flats or pits. Grease the locking device and check to make sure it locks correctly.

- Ring and pintle: Look over these for damage and wear. They also need locking and double-checks to ensure everything is working as intended.

- Electric brakes: Look for wear and test brake operation. Check their current draw, modulation and power output.

Annual Maintenance

There are also maintenance tasks that don’t need doing as often, but you should still perform them once a year:

- Electrical systems: Inspect the entire electrical system, including wiring, connectors and lights. Replace any damaged wires or bulbs and ensure proper grounding.

- Floor and deck: Check the trailer’s floor and deck for weak spots, cracks or rot. Repair or replace damaged sections promptly to maintain structural integrity.

- Rust prevention: Examine all metal components carefully to identify any flaws in the finish. Treat and paint any areas that are corroding or prone to rust. Rust can weaken the trailer’s frame and components, so preventing it is crucial.

- Frame inspection: Check the trailer’s frame for signs of bending or damage. Frame issues require immediate attention to ensure safe towing.

Trailer Repairs You Should Avoid Doing Yourself

While there are many trailer maintenance steps you can perform yourself, some tasks are best left to the professionals to ensure your hauler meets safety and performance standards. If you need these maintenance tasks performed, always request expert assistance:

- Welding: Welding is a specialized skill requiring extensive training and experience. Improper welding can weaken the trailer’s structural integrity, leading to safety hazards. If you need welding performed on your trailer, take it to a professional to ensure the welds’ strength and safety.

- Axle inspection and replacement: Have a professional inspect axles annually for wear, alignment issues or damage. Replacing axles involves heavy components and precise alignment. Incorrect installation can result in handling problems, posing a risk on the road.

- Suspension overhauls: Repairing or replacing suspension components requires extensive knowledge of this system. Mistakes can lead to imbalanced weight distribution and reduced stability.

- Electrical system rewiring: Rewiring a trailer’s electrical system is complex. Errors can lead to electrical problems, shorts or malfunctioning lights, compromising safety.

- Brake system repairs: Brake systems are critical for safety. Incorrect repairs may result in brake failure, endangering you and others on the road.

- Frame straightening: Attempting to straighten a bent frame without proper equipment and expertise can worsen the issue or compromise structural integrity.

- Roof repairs: Repairing leaks or trailer roof damage requires sealing and structural work. Improper repairs can lead to water damage and weakening of the trailer’s structure.

- Hitch modifications: Modifying the hitch or coupling system can impact towing stability and safety. Changes should be made by experts who understand trailer dynamics.

- Floor replacement: Replacing the trailer’s floor may involve structural work, and it demands the right expertise and equipment to be completed in a way that promotes proper weight distribution. You should allow professionals to perform any floor replacements to maintain floor safety and stability.

- Wheel bearing replacement: While greasing wheel bearings can be part of routine maintenance practices, full replacement is best left to professionals.

- Gas-related repairs: Repairs involving gas lines or propane systems are dangerous. Let certified technicians handle these tasks to prevent gas leaks or other hazards.

Get Expert Trailer Services From Big Tex Trailer World

You deserve the best when it comes to your trailer’s safety, reliability and longevity. At Big Tex Trailer World, we’re dedicated to providing expert trailer services that go above and beyond. Our team of skilled technicians understands trailers inside and out. From routine maintenance to complex repairs and high-quality part sales, we’re here to help.

Whether you need a few trailer maintenance tips to keep your hauler in shape between planned service appointments or an urgent repair to get you back on the road, our team is ready to provide top-notch service. You’ll enjoy peace of mind knowing your trailer is in capable hands. Reach out to Big Tex Trailer World today to let us know how we can assist you.